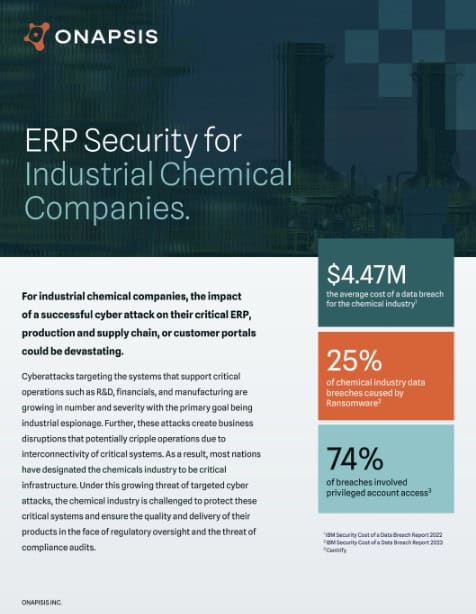

For industrial chemical companies, the impact of a successful cyber attack on their critical ERP, production and supply chain, or customer portals could be devastating.

Cyberattacks targeting the systems that support critical operations such as R&D, financials, and manufacturing are growing in number and severity with the primary goal being industrial espionage. Further, these attacks create business disruptions that potentially cripple operations due to interconnectivity of critical systems. As a result, most nations have designated the chemicals industry to be critical infrastructure. Under this growing threat of targeted cyber attacks, the chemical industry is challenged to protect these critical systems and ensure the quality and delivery of their products in the face of regulatory oversight and the threat of compliance audits.

Key Risk Factors

Increasing ERP System Attacks

Cyber attacks targeting chemical companies are on the rise. Successful attacks on critical ERP systems can be particularly devastating with wide-ranging and significant business impact due to greater interconnectivity up and down the value chain.

Digitization and Interconnectivity

The focus on streamlining operations and creating more efficient processes is transforming supply chains into more localized, digitized, and interconnected systems. This makes chemical companies more agile and able to respond to supply and demand changes. However, this deeper interconnection greatly increases potential unmonitored risks.

Critical Infrastructure Regulations

Chemical companies, designated as critical infrastructure, are classified as high-risk and subject to strict governmental regulations. Failing to comply with audit regulations can result in significant financial impacts to the organization including fines as well as suspension of production.

Key Challenges

Limited Visibility for Security

Chemical companies have ERP applications and assets distributed across a complex and interconnected landscape (IT and OT). This means full visibility of the attack surface is difficult as is mitigating risk to the systems that support connected supply chains, production, and externally exposed applications.

Secure Digital Transformation

Digitization projects streamline operations and increase efficiencies, but they can favor expediency over security. Monitoring critical systems and ensuring that SAP code is developed securely when architecting new applications that affect the supply-chain is critical.

Security Controls for Compliance

Regulatory compliance generally requires a large number of time-consuming, manual, and repetitive tasks to collect data. Identifying unmonitored or vulnerable ERP assets and automating these processes greatly accelerates audit preparation and helps avoid violations.

Solution

Onapsis Provides a Better Approach to ERP Security

Fortunately, securing your complex ERP landscape doesn’t have to be complicated, even with all the advanced threats and attacks out in the wild.

That’s where Onapsis comes in.

As the undisputed experts in business application security with the most prolific threat research team for SAP and Oracle, Onapsis has been on the frontlines securing the world’s leading heavy and discrete manufacturers for over a decade now.

With Onapsis, you get complete 360 degree security for your critical ERP applications, helping you:

- Automate security tasks for a faster, less resource intensive, process for compliance audits

- Manage risk with specific threat research, analysis, and monitoring so your team can effectively take action

- Integrate with existing security resources so familiar ticketing systems and SIEMs can bring ERP security into SOC playbooks

Case Study

F500 Global Chemical Manufacturing Company Reduces Development Time To Build Secure, Compliant, SAP Applications

Challenge

A global chemical company relies on SAP with several business units developing custom code for these business-critical applications. However, the organization struggled to maintain their development cycles at a pace that aligned with the speed of their business, finding it difficult to implement changes without impacting existing system performance or introducing security or compliance issues.

Solution

By using Onapsis Control, this company universally automated their code scanning, gated and analyzed all transports, and reduced their development costs and time investments, automatically scanning hundreds of thousands of lines of codes in minutes. Deep visibility into custom code and transports prevented bad code from entering critical production environments and adversely impacting system performance and security.

Learn more about how Onapsis helps chemical companies protect the systems and data supporting their supply chain, customer portals, production, and other business-critical operations at onapsis.com/fb-manufacturing

Reference

1 IBM Security Cost of a Data Breach Report 2022

2 IBM Security Cost of a Data Breach Report 2023

3 Centrify